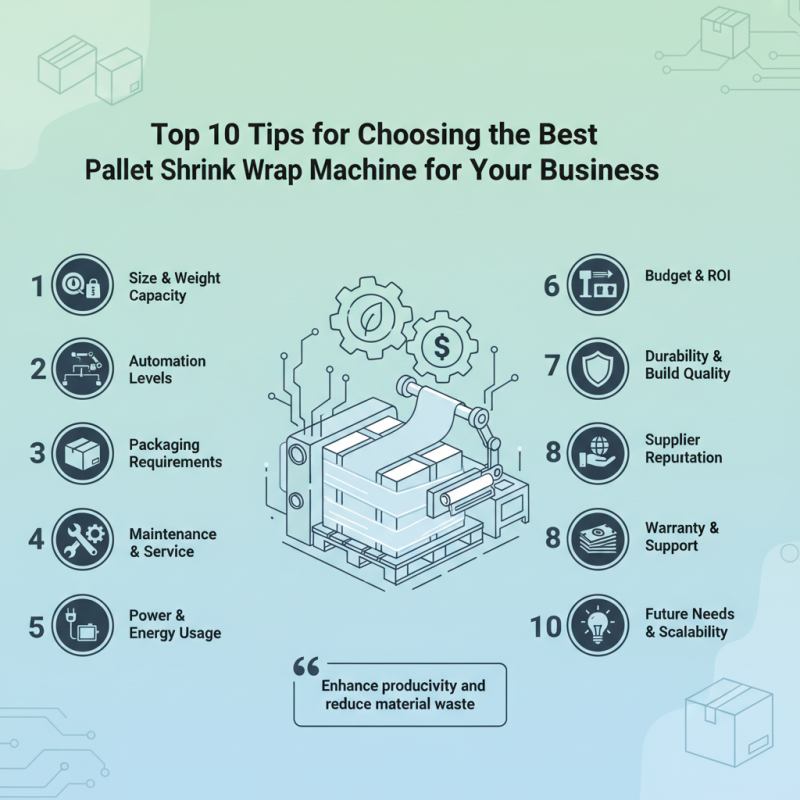

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

In today's fast-paced business environment, choosing the right equipment is crucial for operational efficiency. One essential machine that plays a significant role in packaging and shipping processes is the pallet shrink wrap machine. According to industry expert John Smith, "Selecting the right pallet shrink wrap machine can enhance productivity and reduce material waste in your packaging line." With various options available in the market, understanding the key features and specifications of these machines is vital for any business looking to improve its logistics and supply chain.

In this guide, we will explore the top ten tips for choosing the best pallet shrink wrap machine for your specific needs. From evaluating the size and weight capacity to considering automation levels, these insights will help you make an informed decision. Furthermore, we will delve into the importance of understanding your packaging requirements to ensure that the pallet shrink wrap machine you choose aligns perfectly with your business goals. By following these expert-backed tips, you can optimize your packaging process and contribute to the overall efficiency of your operations.

Understanding the Importance of Pallet Shrink Wrap Machines for Businesses

Pallet shrink wrap machines play a crucial role in streamlining the packaging process for businesses, especially those involved in logistics and warehousing. According to a report by the Freight Transport Association, efficient packaging can lead to a 30% reduction in shipping costs, clearly highlighting the significance of these machines. The right pallet shrink wrap machine not only protects products from moisture, dirt, and damage during transit but also enhances the overall aesthetic of the packaging, contributing to improved customer satisfaction and brand perception.

When selecting the most suitable machine for your operations, it's essential to consider several factors. First, evaluate the machine's production speed to ensure it can meet your throughput requirements. Additionally, be mindful of the wrap quality; using high-quality film can provide better protection and reduce material costs in the long run. Another tip is to investigate the machine’s ease of operation and maintenance; user-friendly interfaces can minimize training time and operational errors.

Investing in a pallet shrink wrap machine can yield significant returns. A study by Packaging Strategies emphasized that companies adopting automated packaging solutions saw up to a 50% increase in productivity. As such, focusing on the right features and capabilities will not only enhance efficiency but ultimately lead to substantial cost savings and a stronger competitive edge.

Key Features to Look for in a Pallet Shrink Wrap Machine

When selecting a pallet shrink wrap machine for your business, certain key features are essential to ensure efficiency and effectiveness in your packaging process. First, pay attention to the machine's capacity. Choose a model that can handle your specific volume of products, ensuring that it can wrap pallets of different sizes without compromising speed or quality. A machine equipped with adjustable settings for different pallet dimensions can provide the versatility needed for varying workloads.

Another crucial feature is the type of sealing method employed. It is important to consider machines that utilize either continuous or standard sealing processes based on your operational needs. Continuous sealing machines offer a streamlined workflow, ideal for high-volume applications, while standard sealers may be more suitable for less frequent, diverse packaging tasks. Additionally, look for machines with robust safety features, such as emergency stop buttons and protective covers, to safeguard operators during use. Moreover, ease of maintenance and availability of spare parts should also be factored into your decision, as a well-maintained machine can significantly minimize downtime and enhance productivity.

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

| Feature | Importance | Considerations |

|---|---|---|

| Machine Speed | High | Choose a machine that can meet your production throughput needs. |

| Film Compatibility | Medium | Ensure the machine can handle various types of shrink film. |

| Power Consumption | High | Look for energy-efficient models to reduce operating costs. |

| Ease of Use | High | Intuitive controls can reduce training time and improve efficiency. |

| Size Adjustability | Medium | Look for machines that easily adjust to various pallet sizes. |

| Durability | High | Select machines made from robust materials for longevity. |

| Maintenance Requirements | High | Evaluate the ease of maintenance and parts availability. |

| Warranty and Support | High | Verify warranty terms and the availability of customer support. |

| Cost | Medium | Analyze total cost of ownership beyond the initial price. |

| Safety Features | High | Ensure the machine has necessary safety protocols for operators. |

Evaluating Different Types of Shrink Wrap Machines Available

When evaluating different types of shrink wrap machines available for commercial use, it's essential to understand the varieties on the market to find the best fit for your business needs. Generally, shrink wrap machines can be categorized into two main types: manual and automatic. According to a recent report by the Freedonia Group, the demand for automatic shrink wrap equipment has surged by approximately 5% annually, reflecting the growing preference for efficiency and reduced labor costs in packaging operations. Manual machines, while more affordable, often require higher labor input and may not be sustainable for high-volume production environments.

In addition to the manual and automatic classifications, businesses can choose between several styles of shrink wrap machines, including L-sealers, foldable sealers, and tunnel machines. L-sealers, for instance, are popular for their compact design and ability to handle moderate volume packaging. By contrast, tunnel shrink wrap machines tend to be ideal for high-volume operations due to their ability to accommodate larger products and consistently apply heat. According to a study by Technavio, the market for tunnel shrink wrap machines is expected to grow significantly, driven by increased demand in industries such as food and beverage, healthcare, and consumer goods. Exceeding production quality and reliability is crucial in making an informed decision on the type of machine that perfectly aligns with your packaging requirements.

Assessing Your Business Needs for Pallet Shrink Wrap Solutions

When selecting the right pallet shrink wrap machine for your business, it's crucial to start by assessing your specific operational needs. According to a recent report by the Freedonia Group, the demand for pallet wrapping machinery is expected to grow by over 5% annually through 2025, driven primarily by the rise of e-commerce and efficient supply chain practices. Understanding the volume of products that need wrapping, the types of materials being used, and the speed of your production line will guide your decision-making process. For instance, businesses with high throughput may require machines that can handle larger volume tasks without compromising on speed or reliability.

Additionally, consider the varying types of shrink wrap machines available in the market, from semi-automatic to fully automatic systems. The Packaging Machinery Manufacturers Institute notes that fully automatic systems can increase productivity by up to 30% compared to their manual counterparts. It’s essential to evaluate not only the initial cost of the machine but also its impact on labor savings, material costs, and overall operational efficiency. Tailoring the choice of machinery to your specific requirements can result in significant long-term savings and a better return on investment, demonstrating how crucial a tailored approach is to selecting the best pallet shrink wrap solutions for your business.

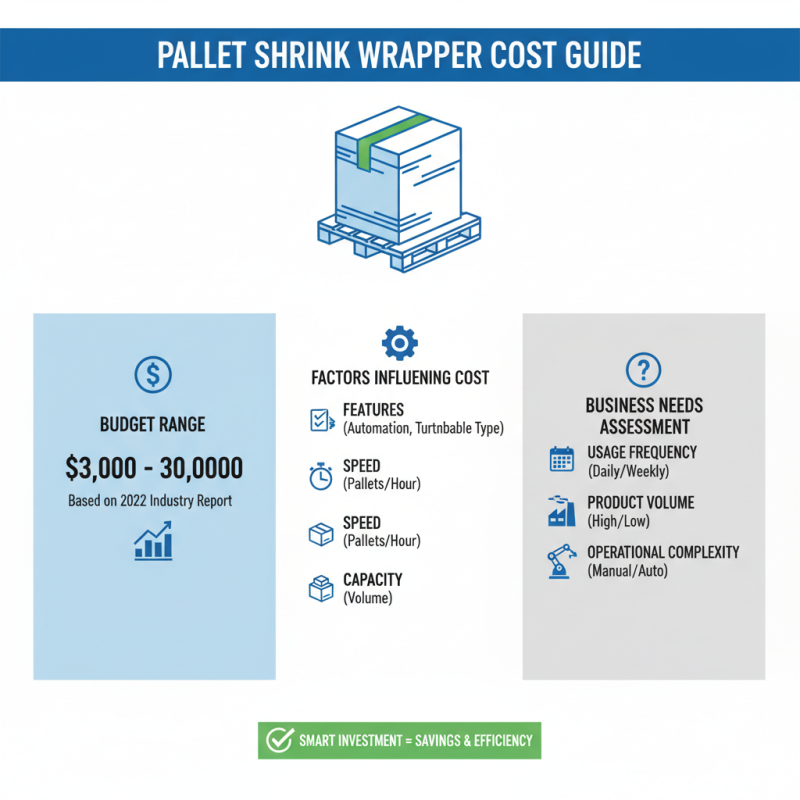

Budget Considerations for Purchasing a Shrink Wrap Machine

When considering the purchase of a pallet shrink wrap machine, budget is often a primary concern for businesses aiming to optimize their packaging operations. According to a 2022 report by Packaging Strategies, companies can expect to spend anywhere from $3,000 to $30,000 for a shrink wrap machine, depending on the features, speed, and production capacity. It’s crucial for businesses to assess their specific needs—evaluating how frequently they will use the machine, the volume of products to be wrapped, and the complexity of operations. Investing in a machine that fits the production scale can provide significant long-term cost savings and efficiency improvements.

In addition to the initial purchase price, businesses should factor in operational costs, such as materials and maintenance. A study from the Food Processing Industry highlights that consumable materials, primarily the shrink film, can add up to over 15% of the total packaging expenses. Moreover, regular maintenance costs can affect the overall budgeting; it’s important for companies to set aside funds for routine checks and repairs to ensure continuous operation. By carefully analyzing both upfront and ongoing costs, businesses can make informed decisions that align with their financial goals while also enhancing their productivity and efficiency in packaging processes.

Related Posts

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs