How to Choose the Best Automatic Pallet Wrapping Machine for Your Business

When it comes to optimizing warehouse operations, selecting the right equipment is crucial for efficiency and productivity. An automatic pallet wrapping machine stands out as an essential tool for businesses looking to streamline their packaging processes. These machines not only save time but also enhance the consistency and security of palletized goods during storage and transit. However, with a plethora of options available in the market, choosing the best automatic pallet wrapping machine for your specific needs can be a daunting task.

Understanding the key features and specifications of automatic pallet wrapping machines is vital to making an informed decision. Factors such as load capacity, wrapping speed, and the type of film used can significantly impact performance and cost-effectiveness. Additionally, considering the space available in your facility and the machine's ease of use and maintenance is critical for long-term satisfaction and operational success. This guide aims to provide valuable insights that will assist you in evaluating various models and selecting the best automatic pallet wrapping machine for your business needs, ensuring that you make a sound investment that enhances your packaging efficiency.

Understanding Automatic Pallet Wrapping Machines and Their Benefits

Automatic pallet wrapping machines are essential tools for businesses that require efficient packaging solutions. These machines utilize stretch film to securely wrap pallets, providing stability during transportation and storage. One of the primary benefits of using an automatic pallet wrapping machine is the consistency it offers. Unlike manual wrapping, which can vary in technique and strength, automated systems apply an even layer of film, ensuring that every load is wrapped uniformly. This consistency not only enhances the protection of products but also reduces the risk of damage during transit.

Another notable advantage of these machines is their ability to optimize labor and time efficiency. With automatic pallet wrappers, businesses can significantly speed up the packaging process, freeing up staff to focus on other important tasks. Additionally, these machines can reduce material waste by utilizing the right amount of film needed for each pallet, which can lead to cost savings over time. By integrating an automatic pallet wrapping machine into operations, businesses can improve their overall productivity and streamline their supply chain processes.

Automatic Pallet Wrapping Machine Analysis

Key Features to Look for in a Pallet Wrapping Machine

When selecting an automatic pallet wrapping machine, it’s crucial to focus on several key features that can significantly impact your packaging efficiency. First and foremost, look for machines with adjustable wrapping speeds and the versatility to accommodate various pallet sizes. This flexibility allows your operation to maximize productivity, especially if your business deals with different products. Additionally, an effective machine should have user-friendly controls and programmable settings to minimize downtime and simplify the training process for staff.

Another vital feature is the system's ability to offer consistent tension and wrapping capabilities. This ensures that the load is securely wrapped, reducing the risk of damage during transport. Integration of sensors or scales can also enhance the wrapping process, as they provide feedback on load stability and alert operators to any issues before packaging. Furthermore, consider machines that come equipped with energy-efficient options, such as automatic film cut-off and pre-stretch capabilities, which not only conserve resources but also reduce operational costs in the long run. By prioritizing these features, businesses can improve their overall productivity and ensure that their pallet wrapping process is both efficient and reliable.

Evaluating Your Business Needs for Pallet Packaging Solutions

When selecting the best automatic pallet wrapping machine for your business, it is essential to first assess your specific packaging needs. According to the 2022 Global Pallet Wrapping Market Report, the demand for automated packaging solutions has increased by approximately 15% over the past five years, reflecting a growing trend among manufacturers and distributors to streamline operations and reduce labor costs. Evaluating your throughput requirements, the volume of pallets processed daily, and the types of products being wrapped will guide you toward the right equipment. Businesses moving over 100 pallets per day often benefit from automatic wrappers that offer speed and efficiency, reducing the packaging time per pallet.

Additionally, consider the dimensions and weight of the pallets that you will be wrapping. Research indicates that up to 30% of packaging-related issues arise from improper wrapping techniques, which can lead to product damage during transport. A quality automatic wrapping machine should provide adjustable settings to accommodate varying pallet sizes and weights, ensuring consistent load stability. By prioritizing versatile machines with technologies for load sensing and tension control, companies can enhance their operational efficiency while minimizing material waste, a significant factor in cost-saving strategies highlighted in the 2023 Supply Chain Sustainability Report.

How to Choose the Best Automatic Pallet Wrapping Machine for Your Business - Evaluating Your Business Needs for Pallet Packaging Solutions

| Pallet Weight (lbs) | Wrap Speed (RPM) | Machine Type | Film Type | Price Range ($) | Ideal Use Cases |

|---|---|---|---|---|---|

| 2000 | 30 | Rotary Arm | Stretch Film | 2500 - 4000 | Warehouse, Distribution Centers |

| 1500 | 25 | Turntable | Pre-Stretched Film | 2000 - 3500 | Small to Medium Enterprises |

| 3000 | 35 | Fully Automatic | Stretch Film | 4000 - 6000 | High Volume Operations |

| 1000 | 20 | Semi-Automatic | Stretch Film | 1500 - 2500 | Light Duty Packaging |

Comparing Different Types of Automatic Wrapping Machines

When selecting an automatic pallet wrapping machine for your business, understanding the different types available is key to making an informed choice. The most common types include stretch wrap machines, shrink wrap machines, and hooding machines.

Stretch wrap machines apply a plastic film tightly around the pallet, which ensures the load remains secure during transportation and storage. These machines can be either semi-automatic or fully automatic, depending on your production requirements. They are ideal for businesses looking for a cost-effective solution with high efficiency.

On the other hand, shrink wrap machines use heat to shrink the wrapping material tightly around the pallet. This method provides a strong, protective layer that is particularly useful for irregularly shaped products. Shrink wrapping can also add a level of moisture resistance, which is an essential consideration in certain industries. Lastly, hooding machines utilize a combination of stretch and shrink methods to create a tamper-proof seal around the pallet, making them suitable for high-volume production environments where product protection is paramount. Each of these options has distinct advantages, and understanding their specific features will help you choose the best machine that fits your business needs.

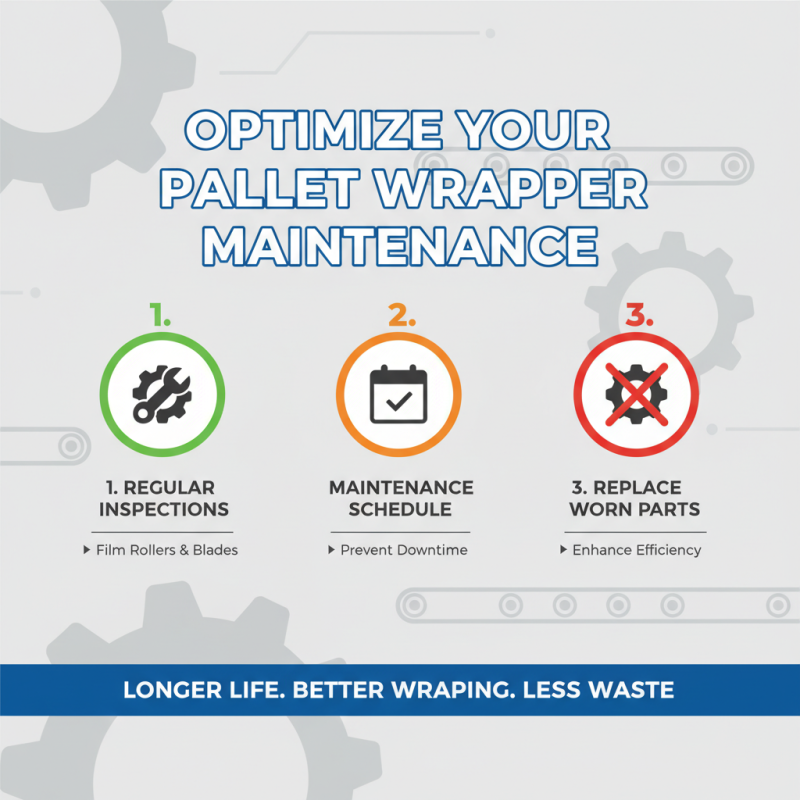

Tips for Maintaining and Optimizing Your Wrapping Equipment

Maintaining and optimizing your automatic pallet wrapping machine is essential to ensure its longevity and efficiency. Regular maintenance routines not only prolong equipment life but also improve the quality of wrapping, minimizing material waste. One important tip is to routinely inspect and replace worn-out parts, such as film rollers and cutting blades, to maintain optimal performance. Creating a maintenance schedule and adhering to it can help avoid unforeseen downtimes and costly repairs.

Another key aspect of optimizing wrapping equipment is to train your staff adequately. Ensure that operators fully understand the machine's features and settings to adapt the wrapping process according to different load types and sizes. Providing ongoing education about best practices and troubleshooting can significantly enhance operational efficiency. Furthermore, keeping the workspace clean and organized around the machine can reduce the risk of accidents and downtime, allowing for smoother daily operations.

Lastly, consider conducting performance audits periodically. Analyze wrapping speed, film usage, and wrap quality to identify areas where improvements can be made. Adjusting machine settings based on these audits can lead to better efficiency and savings over time. By focusing on these maintenance and optimization strategies, you can ensure that your automatic pallet wrapping machine meets the demands of your business effectively.

Related Posts

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Why You Need a Plastic Banding Machine for Your Packaging Operations

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Essential Tips for Choosing the Best Automatic Banding Machine for Your Business

-

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business