2026 How to Choose the Best Automatic Box Taping Machine for Your Business?

Choosing the right automatic box taping machine is crucial for efficiency. A suitable model can streamline your packaging process. With the right machine, labor costs decrease, and productivity increases significantly.

Today’s market offers various options. Each automatic box taping machine has unique features and specifications. It’s vital to understand your specific needs before making a decision. Consider factors like tape type, speed, and user-friendliness.

Buying an automatic box taping machine isn’t just about price. You must assess the long-term benefits it brings to your business. Sometimes, the cheapest option might not be the best in quality. Reflect on your requirements carefully, as this choice can impact your operation's effectiveness and overall success.

Understanding Your Business Needs for a Taping Machine

Choosing the right automatic box taping machine starts with understanding your unique business needs. Consider the scale of your operations. Are you packing hundreds or thousands of boxes daily? This detail significantly influences the machinery you should explore. For small businesses, a simpler, less expensive model may suffice. Larger operations often require faster, more durable machines.

Think about the types of boxes you use. Are they standard sizes or custom dimensions? If your boxes vary in shape and size, you'll need an adaptable machine. Test different machines to see what works best. This may take time and effort but helps in making an informed decision. Remember, a machine too advanced can lead to frustration. It may not fit your workflow, creating unnecessary challenges.

Consider the future too. Will your business grow? Investing in a machine that meets current needs and allows for upgrades or adjustments is vital. It’s easy to become overwhelmed by the options available. Take a step back and reflect on what you truly need. Sometimes, simpler solutions are more effective than complex systems.

Types of Automatic Box Taping Machines Available in the Market

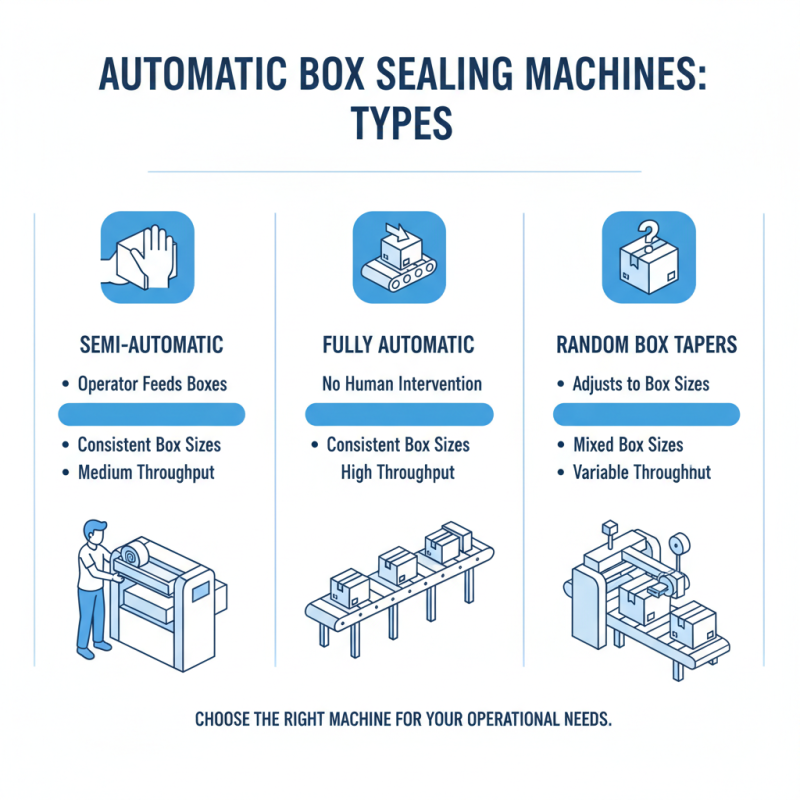

When selecting an automatic box taping machine, it's essential to understand the various types available. There are three primary categories: semi-automatic, fully automatic, and random box tapers. Each type has unique features catering to specific operational needs.

Semi-automatic machines require manual intervention to some degree. They work well for small to medium-sized businesses needing flexibility. Fully automatic machines streamline processes for larger operations, handling various box sizes without manual setup. Random box tapers adjust to different box dimensions automatically, enhancing efficiency in diverse setups. According to a report by Smithers Pira, the demand for automatic machinery in packaging has grown by 5.6% annually from 2018 to 2023.

Tips: Consider your production rate. If your business handles numerous box sizes, a random box taper may save time. Look for user-friendly interfaces to ease operation training. Do your research by analyzing your workflow and projected growth. Exploring these types will ensure the best fit for your production goals while optimizing costs and performance.

Key Features to Look for in a Box Taping Machine

When selecting an automatic box taping machine, several key features demand attention. Adhesive types play a crucial role in ensuring optimal performance. Some machines use acrylic adhesives, which are effective for various temperatures and surfaces. According to a recent industry report, 70% of packaging firms prefer machines that allow adhesive customization. This flexibility can enhance efficiency and reduce waste.

Another vital aspect is the machine's speed. Some models can tape boxes at rates exceeding 20 boxes per minute. This can significantly increase throughput in high-demand environments. However, speed should not compromise accuracy. Machines with adjustable tape tension provide better control. This adjustment helps prevent tape breakage or misalignment. Data shows that improper tape application can lead to a 15% increase in transportation costs due to product damage.

Finally, ease of maintenance is essential to consider. Regular upkeep can prolong the machine's life and ensure consistent performance. Some machines offer user-friendly features such as tool-free access for quick adjustments. However, many operators neglect this aspect, leading to increased downtime. Maintenance training can reduce these issues and save on repair costs, which average around 5% of the equipment's price each year.

Evaluating Cost vs. Performance for Your Taping Needs

Choosing the right automatic box taping machine for your business is a complex decision. Cost and performance are often at odds. A machine that is cheaper may sacrifice quality or speed. You need to understand your specific needs before making a choice.

Performance metrics can include sealing speed, tape width compatibility, and ease of operation. A machine that can handle larger boxes may be more expensive. Evaluate how often you deal with different box sizes. Is it worth investing in a more versatile machine? You will have to face the trade-offs. Sometimes, the cheapest option leaks or requires frequent adjustments.

Think about maintenance costs as well. A lower upfront cost can lead to higher long-term expenses. Maintenance can eat into your budget. Consider your production volume. Will a mid-range machine handle your workload over time? Sometimes the most expensive model isn't the best fit. Reflecting on these aspects will lead you to a more informed decision.

2026 How to Choose the Best Automatic Box Taping Machine for Your Business? - Evaluating Cost vs. Performance for Your Taping Needs

| Feature | Machine A | Machine B | Machine C |

|---|---|---|---|

| Price ($) | 1,200 | 1,500 | 1,800 |

| Speed (boxes/min) | 30 | 25 | 20 |

| Tape Width (inches) | 2 | 2.5 | 3 |

| Power Consumption (W) | 150 | 200 | 250 |

| Maintenance Cost/Year ($) | 200 | 250 | 300 |

| Warranty (years) | 2 | 1 | 3 |

Maintenance Tips for Optimal Performance of Taping Machines

Maintaining an automatic box taping machine is crucial for optimal performance. Regular maintenance can significantly extend the machine's lifespan and improve productivity. According to an industry report, proper upkeep can enhance efficiency by up to 30%. This means less downtime and more boxes taped per hour.

Cleaning components regularly is key. Dust and adhesive residue can impede functionality. A monthly deep clean is recommended, including the tape path and rollers. Neglecting this may lead to uneven tape application. In fact, studies show that improper maintenance increases the risk of machine failures by 40%.

Regularly checking the tension and alignment of the tape can prevent jams. Misalignment can cause delays, impacting your workflow. A simple realignment can restore smooth operation. Not all employees may be trained on these tasks. This gap can lead to oversights. Investing in staff training can yield long-term benefits, optimizing both machine performance and overall output.

Related Posts

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Top Benefits of Using Strapping Machines in Modern Packaging Solutions

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

10 Essential Tips for Choosing the Right Stretch Wrap Machine?

-

Semi Automatic Strapping Machine Tips for Optimal Performance?