How to Choose the Best Air Pillow Machine for Your Packaging Needs

When it comes to optimizing your packaging process, selecting the right tools is crucial for efficiency and cost-effectiveness. One essential piece of equipment that has gained significant traction in the packaging industry is the air pillow machine. This innovative device creates inflatable cushioning for products, offering superior protection during transit while also minimizing materials used. As businesses strive to enhance their packing strategies, understanding the various types of air pillow machines available and their suitability for specific packaging needs has become increasingly important.

Choosing the best air pillow machine requires careful consideration of several factors, including production volume, desired pillow dimensions, and the material used for inflation. With a variety of options on the market, it can be overwhelming to determine which machine fits your operational requirements best. Additionally, evaluating features such as ease of use, maintenance needs, and cost of consumables can impact your decision-making process. This guide aims to provide insights into making an informed choice, ensuring that your packaging procedures are not only efficient but also align perfectly with your business objectives. Ultimately, investing in the right air pillow machine can enhance the overall effectiveness of your packaging, leading to improved customer satisfaction and reduced shipping costs.

Understanding Air Pillow Machines and Their Benefits for Packaging

Air pillow machines have become essential tools in the packaging industry, primarily due to their ability to provide effective cushioning for products during shipping and storage. These machines produce inflatable cushions that can be strategically placed around items, minimizing movement and reducing the risk of damage. The lightweight nature of air pillows also contributes to cost savings in shipping, as they help keep the overall package weight down. This method of packing is not only efficient but also environmentally friendly, as air pillows require less material compared to traditional packing methods.

Furthermore, using air pillow machines can enhance the overall efficiency of a packaging operation. They are typically easy to use and can produce a significant volume of cushions quickly, making them suitable for businesses with high packaging demands. The customization options available, such as different sizes and shapes of pillows, allow businesses to tailor the packaging solution to their specific needs. By investing in an air pillow machine, companies can streamline their packaging processes, improve product safety, and ultimately provide a better experience for their customers through reduced damage rates during transit.

Key Factors to Consider When Choosing an Air Pillow Machine

When selecting the best air pillow machine for your packaging requirements, several key factors should be taken into account. First and foremost, the machine's production speed is crucial, especially if your business demands high volumes of packaging. Evaluate how quickly the machine can produce air pillows, as efficiency in this area can significantly impact overall workflow and productivity. Additionally, consider the machine's capacity and whether it can accommodate the size and shape of the air pillows that you need for your products.

Another important aspect is the ease of use and maintenance of the air pillow machine. A user-friendly interface can streamline your packaging process, reducing the time needed for training staff and minimizing the potential for errors. Furthermore, look into the maintenance requirements of the machine. Opt for models that offer easy access for cleaning and repairs, along with reliable customer support from the manufacturer to minimize downtime.

Lastly, consider the cost of consumables, such as plastic film, as this can affect the long-term operational costs of your packaging system. Prioritize machines that are economically viable without sacrificing quality or performance to ensure your packaging needs are met effectively.

Different Types of Air Pillow Machines and Their Applications

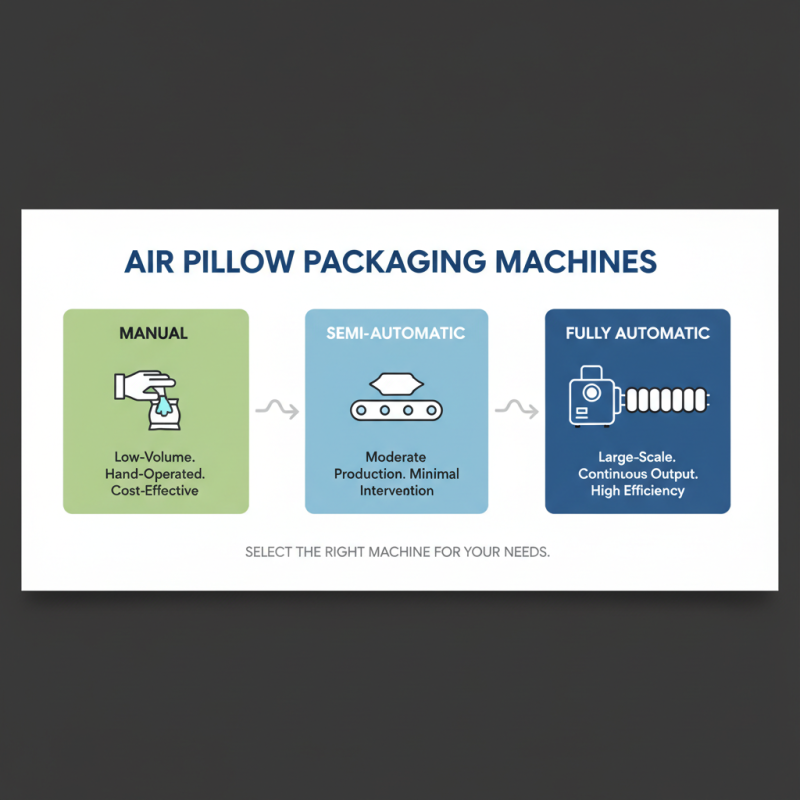

When selecting an air pillow machine, it is essential to understand the different types available and their specific applications in packaging. Air pillow machines can be broadly categorized into three main types: manual, semi-automatic, and fully automatic systems. Manual air pillow machines are ideal for low-volume operations, allowing users to create air pillows by hand, which can be cost-effective but labor-intensive. In contrast, semi-automatic machines streamline the process by requiring minimal manual intervention, making them suitable for moderate production needs. Fully automatic air pillow machines offer the highest efficiency, producing high volumes of pillows continuously and are perfect for large-scale operations.

According to industry data, the demand for air cushioning solutions has surged, with the global air pillow market projected to grow at a CAGR of 5.8% over the next five years. This growth is driven by the rising e-commerce sector, where protective packaging is crucial for safeguarding products during shipping. Businesses must evaluate their packaging needs carefully and consider factors like production speed, space requirements, and budget constraints when choosing the right machine.

Tips for choosing the best air pillow machine include assessing your packaging volume—if your operation requires a high number of air pillows daily, a fully automatic machine may be the best investment. Additionally, evaluate the available space in your facility; some machines require a larger footprint than others. Finally, consider the types of products you will be packaging to ensure the air pillow size is optimal for effective cushioning.

Evaluating Performance and Efficiency of Air Pillow Machines

When evaluating the performance and efficiency of air pillow machines for packaging needs, it is essential to consider factors such as production speed, film width compatibility, and energy consumption. According to a recent industry report by Packaging Strategies, modern air pillow machines can produce up to 1,200 air pillows per hour, significantly increasing packaging efficiency for businesses looking to streamline their operations. Moreover, machines offering adjustable film widths between 10 to 28 inches can accommodate a variety of packaging requirements, making them versatile solutions for different products.

Additionally, energy efficiency plays a crucial role in the overall operating costs of air pillow machines. The Institute of Packaging Professionals reported that machines designed with energy-saving modes can reduce electricity consumption by up to 30%, which contributes to lower operational expenses in the long run. For companies focused on sustainability, investing in equipment that prioritizes eco-friendly materials can further enhance their packaging strategy.

Tip: When choosing an air pillow machine, consider performing a cost-benefit analysis that includes both initial investment and potential savings from energy-efficient models.

Tip: Don't overlook the importance of maintenance and support services; select a machine from a provider that offers comprehensive technical support to minimize downtime. By carefully assessing these factors, you can ensure that your air pillow machine meets your packaging needs effectively and efficiently.

Performance and Efficiency of Air Pillow Machines

Maintenance and Support for Your Air Pillow Machine Choice

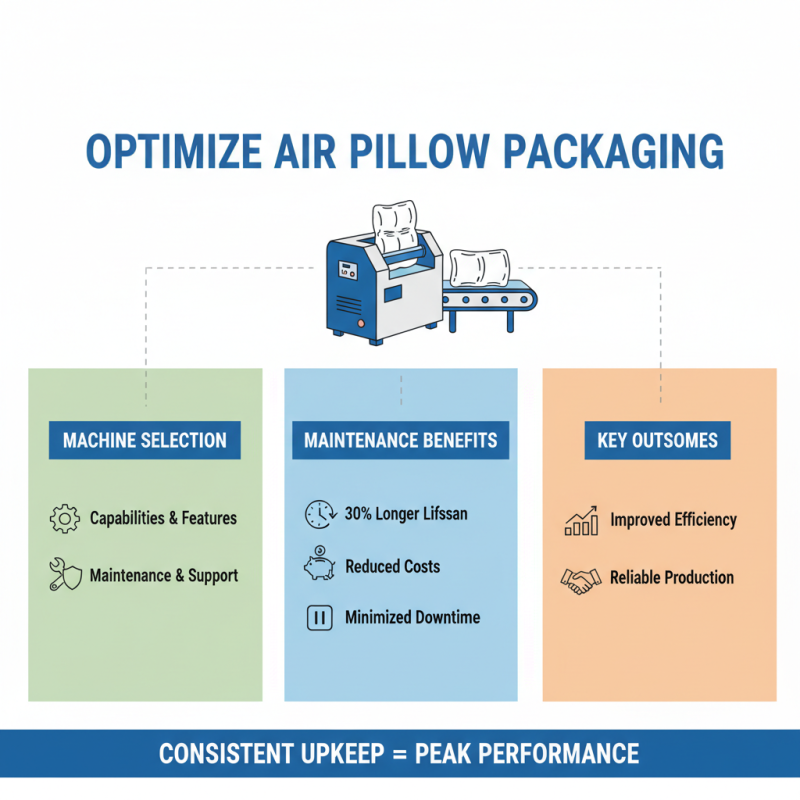

When selecting an air pillow machine, it’s essential to consider not just the machine's capabilities but also the maintenance and support that come with it. Regular maintenance is crucial for ensuring optimal performance and longevity of the equipment. According to industry reports, consistent upkeep can extend the lifespan of an air pillow machine by up to 30%, significantly reducing the long-term costs associated with equipment failure and replacement. A well-maintained machine not only improves packaging efficiency but also minimizes downtime, which is critical in a fast-paced production environment.

Support services are equally important in your air pillow machine choice. Access to reliable technical support can make a significant difference, especially during peak operational times. Studies show that companies with robust support systems can resolve equipment issues 50% faster than those without. This efficiency translates to less disruption in the production line and can enhance overall operational productivity. When evaluating your options, consider the availability of support services, including training for your staff and responsive technical assistance to handle any issues promptly, ensuring that your packaging needs are consistently met.