Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

In today's fast-paced industrial landscape, efficiency and reliability in packaging processes are paramount. A plastic strapping machine has emerged as a crucial tool for businesses aiming to streamline their operations. According to industry expert John Smith, a leading authority in packaging solutions, "The adoption of plastic strapping machines can significantly enhance the speed and integrity of packaging, thereby reducing operational costs." This statement underscores the transformative impact that this equipment can have on various packaging applications.

As companies increasingly seek ways to optimize their workflows, the benefits of integrating a plastic strapping machine into the packaging line become evident. From improved package stability to enhanced security during transit, these machines offer multiple advantages that can lead to higher customer satisfaction and reduced product damage. Furthermore, by eliminating manual strapping processes, businesses can not only save time but also allocate their workforce to more complex tasks that require human oversight. Embracing this technology is not just a trend; it represents a strategic move towards operational excellence and cost-effectiveness in the packaging sector.

Advantages of Plastic Strapping Machines in Modern Packaging

Plastic strapping machines have become an integral part of modern packaging solutions, offering numerous advantages that enhance efficiency and effectiveness. One of the most significant benefits is the ability to improve product security during transit. The durable nature of plastic strapping ensures that packages remain tightly bound, reducing the likelihood of damage due to shifting or movement. This reliability is essential for businesses aiming to maintain high standards of quality and customer satisfaction.

Moreover, plastic strapping machines contribute to a significant reduction in labor costs and time. Automated strapping systems streamline the packaging process, allowing for faster application compared to manual methods. This efficiency not only speeds up production lines but also minimizes the potential for human error, leading to consistent results across various batches of products. Additionally, the adaptability of plastic strapping machines allows them to cater to different packaging styles and sizes, making them suitable for a wide range of industries. As companies continue to seek innovative solutions to optimize their packaging operations, the advantages of plastic strapping machines remain clear.

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

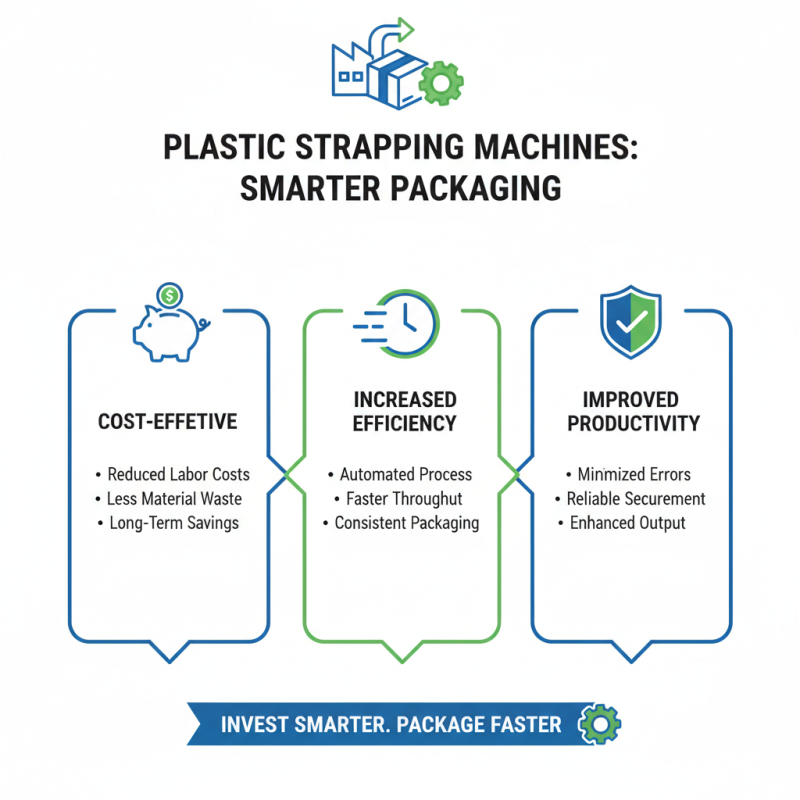

Increased Efficiency in Packaging Operations through Automation

In today's fast-paced packaging environment, the use of a plastic strapping machine has become essential for enhancing operational efficiency. By automating the strapping process, companies can significantly reduce the time and labor costs associated with manual packaging. These machines enable consistent and reliable strapping of products, ensuring that packages are securely bound and ready for transport. This not only streamlines the workflow but also minimizes the risk of product damage during shipping.

Tips for implementing a plastic strapping machine include ensuring proper training for staff to ensure optimal usage. A well-informed team can maximize the benefits of the machine, reducing errors and increasing overall productivity. Additionally, regularly maintaining and servicing the equipment can prevent potential downtimes and prolong its lifespan, further enhancing operational efficiency.

Another advantage of automation through the use of these machines is the ability to adapt to various packaging needs. With adjustable settings, a plastic strapping machine can cater to different product sizes and shapes, making it a versatile tool in any packaging operation. Adjusting the tension levels as required ensures that each package is strapped securely without damaging the contents, which is crucial for maintaining product integrity during transit.

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

| Benefit | Description | Impact on Efficiency |

|---|---|---|

| Increased Speed | Automated strapping reduces the time required for packaging. | Enhances throughput. |

| Consistent Tensioning | Guarantees uniform tension across all packages. | Reduces the risk of damage during transit. |

| Reduction in Labor Costs | Less manual labor is required for packaging tasks. | Decreases overall operational expenses. |

| Improved Safety | Automated processes minimize worker exposure to injuries. | Promotes a safer work environment. |

| Versatile Applications | Can be used for various products and package sizes. | Enhances flexibility in packaging operations. |

| Quality Control | Consistent strapping quality improves package integrity. | Reduces product returns due to packaging failures. |

| Space Efficiency | Compact machinery saves floor space in facilities. | Maximizes available workspace. |

| Cost-Effectiveness | Reduction in the amount of strapping material wastage. | Lower packaging costs over time. |

| Enhanced Branding | Professional-looking packages reinforce brand image. | Improves customer perception. |

| Sustainability | Use of recyclable materials promotes eco-friendliness. | Supports green packaging initiatives. |

Cost-Effectiveness of Using Plastic Strapping Machines in Industries

Plastic strapping machines are increasingly becoming a staple in various industries due to their cost-effectiveness and efficiency in packaging solutions. By automating the strapping process, businesses can significantly reduce labor costs associated with manual strapping methods. This automation not only speeds up the packaging process but also minimizes human error, leading to better overall productivity. Over time, the initial investment in a plastic strapping machine can result in substantial savings, considering the reduction in labor hours and the enhanced throughput.

In addition to labor savings, plastic strapping machines also help in minimizing material waste. They utilize strapping materials efficiently, ensuring that each package is secure without excess use of straps. This careful distribution of materials not only lowers costs but also aligns with eco-friendly practices, reducing the overall environmental impact of packaging operations. Moreover, many machines are designed to work with various types of strapping materials, providing flexibility for industries to adapt their packaging to suit specific requirements without incurring high material costs. Overall, the cost-effectiveness of plastic strapping machines makes them an invaluable investment for businesses looking to enhance their packaging processes while maintaining budgetary constraints.

Enhanced Load Stability and Security with Plastic Strapping Solutions

The significance of load stability and security in packaging cannot be overstated, especially in industries where goods are transported over long distances or stored in demanding environments. Utilizing a plastic strapping machine enhances load stability by providing a robust and reliable means of securing products. According to a report from the Freedonia Group, the global market for strapping materials is projected to exceed $10 billion by 2025, a testament to the increasing reliance on such packaging solutions for enhanced protection during transit.

Plastic strapping has notably evolved to provide superior tensile strength and flexibility, outperforming traditional materials like steel in many applications. For instance, a study from Smithers Pira indicates that the use of plastic strapping can reduce the risk of product damage by up to 50% compared to non-strapped loads. This is particularly vital in sectors such as food and beverage, where product integrity impacts not only profitability but also consumer safety.

Furthermore, modern plastic strapping machines are designed for efficiency, allowing operators to secure loads quickly and effectively. This not only improves throughput but also minimizes the labor required for packaging tasks. Research has shown that automating the strapping process can lead to a 20-30% reduction in production costs, thereby reinforcing the overall security of goods while optimizing operational efficiency. In an era where supply chain resilience is crucial, investing in plastic strapping technology is an essential strategy for any business aiming to safeguard its products.

Versatility and Adaptability of Plastic Strapping Machines in Applications

Plastic strapping machines offer incredible versatility and adaptability, making them suitable for a wide range of applications. Their design allows for the use of various strap materials, including polypropylene and polyester, which can meet the specific needs of different industries. Whether it's securing pallets in warehouses, bundling products for shipping, or packaging goods for retail, plastic strapping machines can efficiently adjust to diverse packaging requirements. This adaptability ensures that organizations can maintain productivity without being constrained by the limitations of manual strapping processes.

Furthermore, the scalability of these machines enhances their application. They can be utilized in small operations or large-scale manufacturing environments, seamlessly fitting into existing workflows. Their ability to handle varying strap sizes and thicknesses allows businesses to tailor their packaging solutions according to product dimensions and weight. Moreover, automated options can integrate with other packing equipment, streamlining the entire packaging process. This flexibility not only boosts operational efficiency but also aligns with the growing demand for customized packaging solutions in an ever-evolving market.