What is an Automatic Pallet Wrapping Machine and How Does It Work?

In the fast-paced world of logistics and warehousing, efficiency and reliability are paramount. One essential tool that facilitates these attributes is the automatic pallet wrapping machine. This innovative piece of equipment is designed to streamline the packaging process by securely wrapping products on pallets, ensuring they remain intact during transportation and storage. As businesses strive to enhance productivity and reduce operational costs, the adoption of automatic pallet wrapping machines has become increasingly popular across various industries.

The function of an automatic pallet wrapping machine extends beyond mere convenience; it offers numerous benefits, including improved load stability and protection against environmental factors. By utilizing stretch film, these machines wrap pallets uniformly, effectively safeguarding the contents from damage. Moreover, the automation aspect significantly reduces the labor involved in the manual wrapping process, allowing workers to focus on more critical tasks, thereby maximizing overall efficiency.

As we delve deeper into the workings of an automatic pallet wrapping machine, it becomes clear how this equipment revolutionizes the packaging industry. Understanding its components and operation not only highlights its significance but also underscores the advancements in technology that are driving this sector forward. Whether in a busy warehouse or a production facility, the automatic pallet wrapping machine stands as a vital asset, transforming how goods are secured for shipment.

Overview of Automatic Pallet Wrapping Machines

Automatic pallet wrapping machines play a crucial role in modern packaging processes, streamlining the way goods are secured and transported. These machines are designed to wrap plastic film around pallets of products, ensuring that items are tightly bundled together for safe storage and shipping. By automating this process, companies can significantly increase efficiency, reduce labor costs, and improve consistency in packaging.

These machines operate using a combination of advanced technology and user-friendly interfaces, allowing operators to easily set the desired wrapping parameters, such as the number of wraps, tension, and speed. The pallet is typically placed on a turntable or in a stretch wrapper, which rotates the load as the film is applied, creating a secure packaging that protects the contents from damage during transit.

The automation removes the manual effort required in hand wrapping and helps maintain a uniform wrapping quality that is essential for effective palletization.

Key Components and Mechanisms of Automatic Pallet Wrappers

Automatic pallet wrapping machines are essential in modern logistics and material handling, designed to enhance the speed and efficiency of wrapping pallets for storage or shipment. The key components of these machines include the film carriage, turntable, and control system. The film carriage serves as the mechanism that dispenses stretch film around the pallet, ensuring that products are securely wrapped to prevent damage during transportation. The turntable rotates the pallet, allowing for uniform application of the film, while the control system enables operators to set specific wrapping parameters such as film tension, number of rotations, and height adjustments, optimizing the wrapping process to accommodate various product sizes and weights.

According to a report by the Research and Markets, the automatic pallet wrapping machine market is projected to grow at a CAGR of 4.5% from 2021 to 2026, driven by the increasing demand for efficient packaging solutions across multiple industries, including food and beverage, pharmaceuticals, and consumer goods. The efficiency and consistency provided by automatic pallet wrappers significantly reduce labor costs and minimize waste, with studies indicating that automated wrapping can decrease wrapping time by up to 50%. Additionally, the integration of advanced features such as photoelectric sensors and variable speed control contributes to enhanced productivity and reduced operational downtime, making these machines a vital investment for companies looking to improve their supply chain operations.

Performance of Automatic Pallet Wrapping Machines

Benefits of Using Automatic Pallet Wrapping Machines in Industry

Automatic pallet wrapping machines are increasingly becoming essential in industrial settings due to their numerous benefits. One of the primary advantages is the significant increase in efficiency and productivity. According to a report by the International Data Corporation, firms adopting automation in their packaging processes have reported a productivity increase of up to 30%. This is attributed to the machines’ ability to wrap pallets more quickly and consistently than manual methods, reducing labor costs and minimizing downtime.

In addition to efficiency, these machines also enhance product protection during storage and transportation. The use of stretch film in automated wrapping creates a tight, secure load that can withstand various physical stresses. According to a study from the Packaging Machinery Manufacturers Institute, the risk of product damage can be reduced by as much as 50% when using automated wrappers compared to manual wrapping. This reduction in damage not only preserves the quality of goods but also significantly decreases costs related to returns and replacements, ultimately leading to a more cost-effective operation for businesses.

Moreover, automatic pallet wrapping machines contribute to a safer working environment. By reducing the need for manual handling, they lessen the risk of workplace injuries, particularly those associated with repetitive strain and heavy lifting. The Occupational Safety and Health Administration reports that implementing automation technologies can lead to a notable decline in workplace accidents, promoting a healthier, more productive workforce. Overall, the integration of automatic pallet wrapping machines within industry settings significantly supports operational efficiency, product safety, and employee well-being.

What is an Automatic Pallet Wrapping Machine and How Does It Work?

| Feature | Description | Benefits |

|---|---|---|

| Operation Speed | Can wrap pallets at speeds of up to 30 pallets per hour. | Increases productivity and efficiency in packaging operations. |

| Ease of Use | Fully automated with user-friendly controls. | Reduces labor costs and minimizes operator training time. |

| Film Usage | Uses stretch film to secure pallet loads tightly. | Improves load stability during transport and storage. |

| Safety Features | Equipped with emergency stop buttons and safety guards. | Enhances workplace safety and reduces accidents. |

| Integration | Can be integrated with conveyor systems and other packaging equipment. | Streamlines the packaging process and workflow. |

Industry Standards and Specifications for Pallet Wrapping Technology

When discussing industry standards and specifications for pallet wrapping technology, it is essential to recognize the various guidelines that govern the materials and processes used. The National Institute of Standards and Technology (NIST) provides frameworks that ensure the reliability and efficiency of automatic pallet wrapping machines. These standards emphasize the importance of using high-quality stretch films that comply with thickness and tensile strength requirements. This is crucial not only for the stability of pallet loads but also for minimizing waste and ensuring cost-effectiveness in packaging and shipping processes.

In addition to material specifications, the design and functionality of automatic pallet wrapping machines must adhere to safety and operational standards set by regulatory bodies, such as OSHA in the United States. These specifications cover aspects like machine ergonomics, safety features, and operational efficiency, which play a vital role in enhancing productivity while ensuring the safety of personnel. Furthermore, regular testing and certification processes help validate a machine’s compliance with industry standards, ensuring that businesses can maintain a high level of quality control throughout their packaging operations.

Current Market Trends and Innovations in Pallet Wrapping Machinery

The pallet wrapping machinery market has witnessed significant innovations in recent years, driven by the need for efficient packaging solutions in various industries. As per a report by MarketsandMarkets, the global pallet wrapping machine market is projected to reach approximately $2.5 billion by 2026, growing at a CAGR of around 4.5% from 2021. This growth is attributed to the increasing demand for automation in packaging processes, aiming to improve productivity and reduce labor costs.

One of the key trends influencing the market is the incorporation of smart technology in pallet wrapping machines. Many manufacturers are now integrating IoT capabilities into their machinery, allowing for real-time monitoring and data analysis. By utilizing predictive maintenance, businesses can minimize downtime and optimize their wrapping operations. Moreover, innovations in stretch film technology, such as pre-stretched and multi-layer films, provide enhanced load stability and reduction in material usage, further promoting sustainability.

Additionally, the focus on energy-efficient machinery is becoming paramount as companies aim to meet stricter environmental regulations. According to P&S Intelligence, the demand for energy-efficient wrapping machines is expected to rise as they significantly lower carbon footprints and contribute to corporate sustainability goals. With these trends, businesses in the logistics and supply chain sectors are better positioned to enhance their packaging processes while aligning with modern sustainability practices.

Related Posts

-

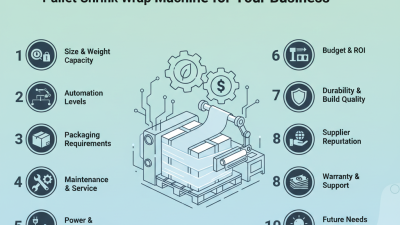

Top 10 Tips for Choosing the Best Pallet Shrink Wrap Machine for Your Business

-

Top 10 Benefits of Using a Plastic Strapping Machine for Packaging Solutions

-

Top 10 Tips for Choosing the Best Box Taping Machine for Your Needs

-

Top 10 Benefits of Using Automatic Stretch Wrap Machines for Your Business

-

Best Air Cushion Machine for Optimal Packaging Efficiency and Cost Savings

-

How to Choose the Best Air Pillow Machine for Your Packaging Needs